Glove machine

- Tel: 0086-15250337149

- E-mail: nixiaochao@gmail.co

Challenged by rising labor costs, the glove industry needs intelligent equipment more urgently. Through years of accumulated technology and experience as the leadino manufacturer, ZBT has developed the latest generation of high-speed & intelligent glove knitting machines, B-Mad99, which has become the benchmark of the industry. B-Mac 99 simplifies the previous mechanica structure and uses multiple motor drivers such as servo and step motors, greatly reduces mechanical parts ano ease mechanical maintenance. Compared with ordinary machines, B-Mac 99 has smaller volume, lower energy consumption, higher speed and higher output. Through centralized computer ordering, centralized setting of required parameters, real-time feedback monitoring eguipment operation, automatic statistics of various data and indicators, and remote real-time monitoring production management efficiency has also been greatly improved. The realization of smart factories in the future has become a possibility.

1. Full-size knitting: Different sizes of gloves can be knitted on the same machine by changing the computer settings and the pins on the needle selection drum. No need to change shaft or any other mechanical parts.

2.Free needle pattern: with specially designed needle selection drum any high or low needle orsinker combination can be used.

3.U2 device (plating feeders):It is specially designed to produce pile-knitted gloves with different materials inside and outside.

4.U3/Zebra:Together with U2 deviceit can produce partially pile-knitted gloves.

5.One touch D3 device: Unlike previous devices,this new and improved device doesn’t affect the little finaer witdhThe upper palm portion below the middle-three finaers is knitted separately from the rest of the palm, which provides independent movement and more comfortable and betterfit.

6.Belt-Drive carriage: it features smooth operationhigh stability and energy efficiency, and precise variable control of carriage movement improves productivity and eases maintenance.

7.Infrared area safety sensor:The new area sensor features an invisible protective shield of infrared beams,which when broken stops the machine automatically.The area sensor reduces the likelihood ofinjury from moving parts.

8.Pineapple pattern device:This device uses a special weaving system and the gloves produced have a geometric shape similar to a honeycomb.This shape can bear the greatest weiaht and toraue with the least amount of material and improves the breathabllity and arip of the glove liner.

9.Stitch density step motor: it can finely adjust the stitch density at very course of the glove,thus the glove can be better shaped to fit fingers and hands.

2.Free needle pattern: with specially designed needle selection drum any high or low needle orsinker combination can be used.

3.U2 device (plating feeders):It is specially designed to produce pile-knitted gloves with different materials inside and outside.

4.U3/Zebra:Together with U2 deviceit can produce partially pile-knitted gloves.

5.One touch D3 device: Unlike previous devices,this new and improved device doesn’t affect the little finaer witdhThe upper palm portion below the middle-three finaers is knitted separately from the rest of the palm, which provides independent movement and more comfortable and betterfit.

6.Belt-Drive carriage: it features smooth operationhigh stability and energy efficiency, and precise variable control of carriage movement improves productivity and eases maintenance.

7.Infrared area safety sensor:The new area sensor features an invisible protective shield of infrared beams,which when broken stops the machine automatically.The area sensor reduces the likelihood ofinjury from moving parts.

8.Pineapple pattern device:This device uses a special weaving system and the gloves produced have a geometric shape similar to a honeycomb.This shape can bear the greatest weiaht and toraue with the least amount of material and improves the breathabllity and arip of the glove liner.

9.Stitch density step motor: it can finely adjust the stitch density at very course of the glove,thus the glove can be better shaped to fit fingers and hands.

1.Non-thread: Through the specially designed carriage, the remaining yarn at the fingertips and between the crotch can be knitted inside the gloves without blowing, which not only saves power, but also improves the quality of the gloves.

2.Automatic overlock device: it eliminates the traditional manualoverlock process, which not only reduces labor costs. but also improves production efficiency.

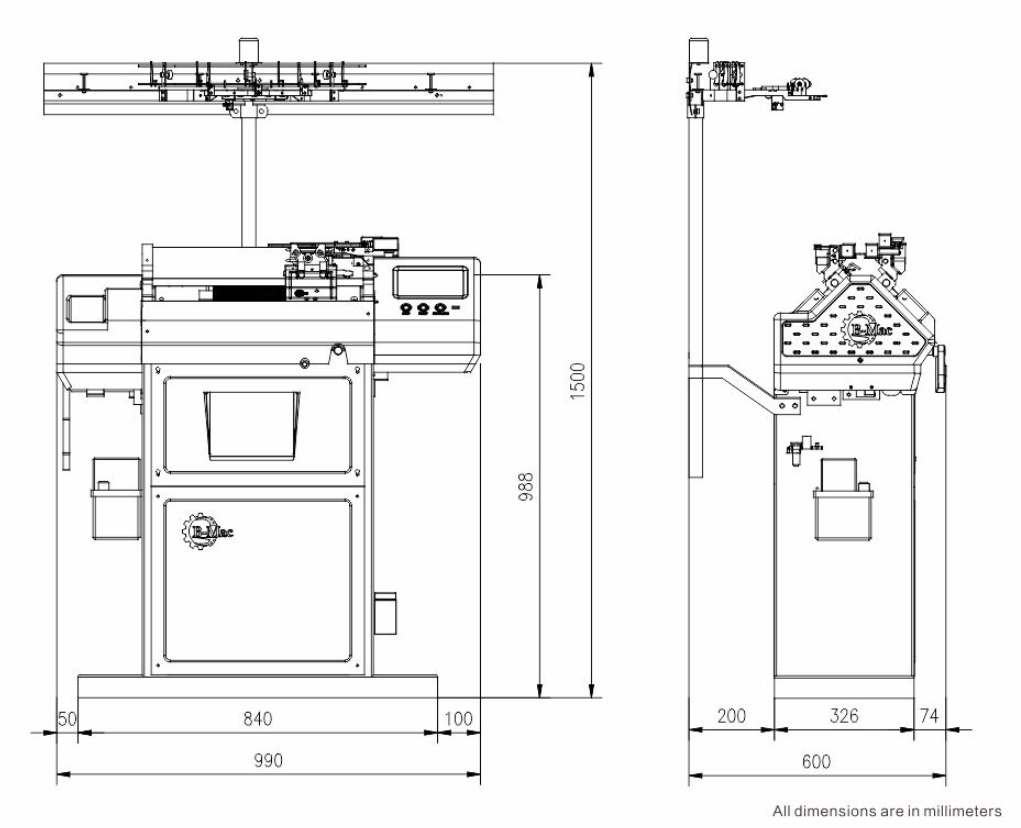

3.Smaller volume: Compared with the old model. B-Mac 99 has a 20% reduction in floor space. More machines can be placed in a limited factory space, increasing overall productivity.

4.Smarter: The powerful integrated computer system can store allthe glove specifications. A large amount of data can be transferred via the USB memory interface, eliminating the need to set it up separately on each machine saving a lot of time. The 7-inch touch screen operation panel adopts a user-friendly design concept, which makes the operation simpler and the display more concise.

5.More energy saving: Theultra-small and ultra-thin carriage can reduce the load of the machine. realize the extremely fast rotation, high-speed operation, reduce the inertial impact force during high-speed operation, and reduce the power consumption by more than 25%.

6.Reinforced crotch device: it can produce gloves with higher friction resistance between the thumb and the forefingerIt’s more suitable for cut-resistant gloves.

7.2-color &3-color devices: it can make gloves with 2 or 3 colors stripes. By using conductive yarn at the fingers. the gloves can be used for touch-screen products.

8.Automatic lubrication: it features lubrication to all required parts, provides sufficient coverage to all parts of the machine for minimized wear and easier maintenance.

9.Elastic yarn motor controller: step motor controls elastic yarn output, intelligently controls the wrist width and ensure the guality of every piece of glove.

2.Automatic overlock device: it eliminates the traditional manualoverlock process, which not only reduces labor costs. but also improves production efficiency.

3.Smaller volume: Compared with the old model. B-Mac 99 has a 20% reduction in floor space. More machines can be placed in a limited factory space, increasing overall productivity.

4.Smarter: The powerful integrated computer system can store allthe glove specifications. A large amount of data can be transferred via the USB memory interface, eliminating the need to set it up separately on each machine saving a lot of time. The 7-inch touch screen operation panel adopts a user-friendly design concept, which makes the operation simpler and the display more concise.

5.More energy saving: Theultra-small and ultra-thin carriage can reduce the load of the machine. realize the extremely fast rotation, high-speed operation, reduce the inertial impact force during high-speed operation, and reduce the power consumption by more than 25%.

6.Reinforced crotch device: it can produce gloves with higher friction resistance between the thumb and the forefingerIt’s more suitable for cut-resistant gloves.

7.2-color &3-color devices: it can make gloves with 2 or 3 colors stripes. By using conductive yarn at the fingers. the gloves can be used for touch-screen products.

8.Automatic lubrication: it features lubrication to all required parts, provides sufficient coverage to all parts of the machine for minimized wear and easier maintenance.

9.Elastic yarn motor controller: step motor controls elastic yarn output, intelligently controls the wrist width and ensure the guality of every piece of glove.

Feedback form contact with us