-

LED touch screen for displaying various knitting related parameters.

LED touch screen for displaying various knitting related parameters. -

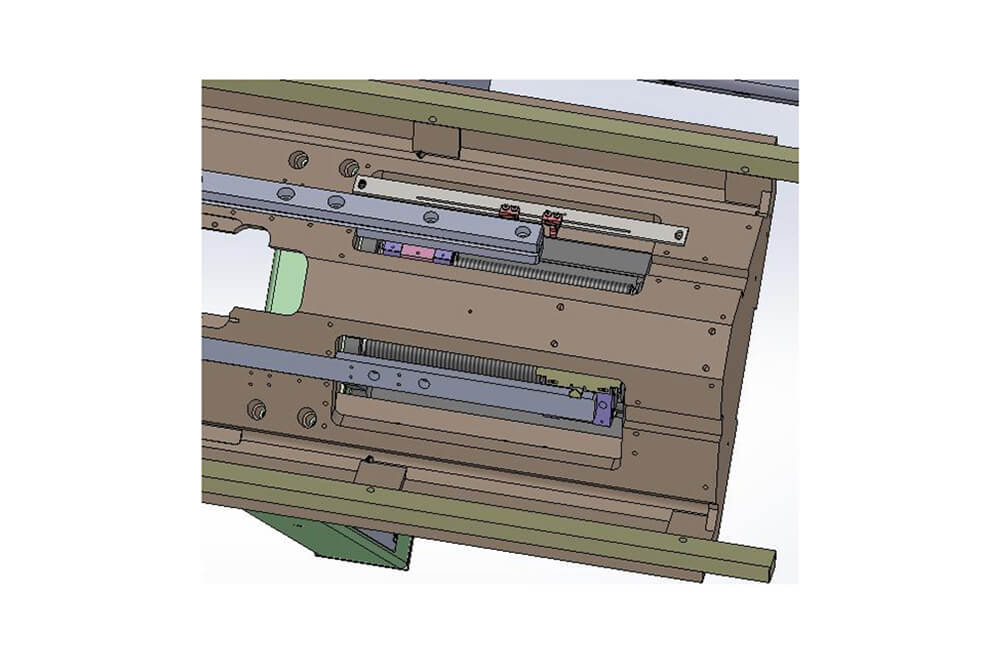

Double side racking, reduce racking movement, thus increasing production efficiency.

Double side racking, reduce racking movement, thus increasing production efficiency. -

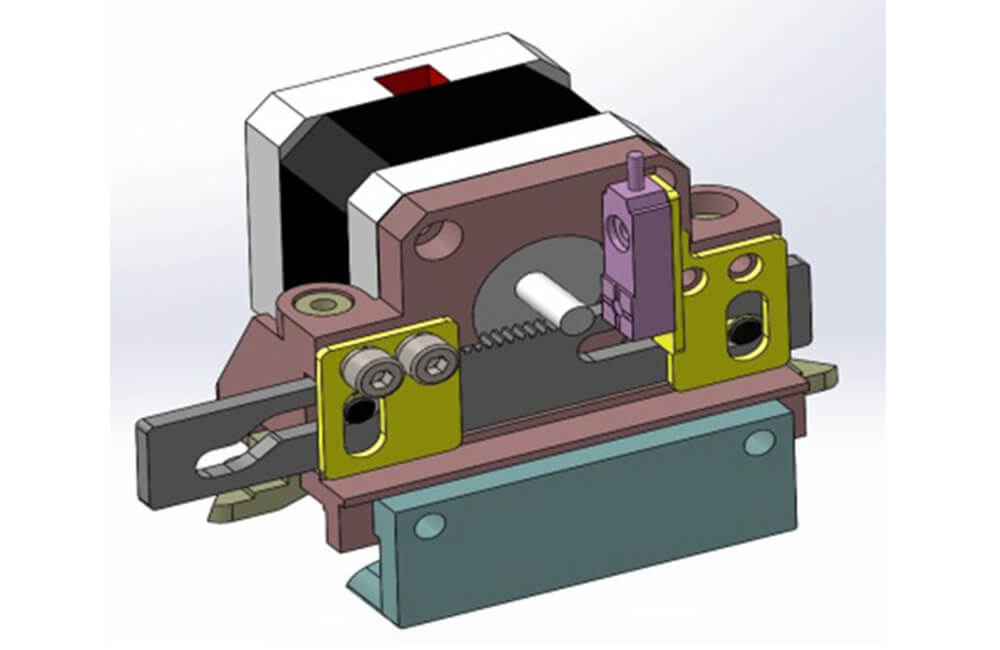

High-performance servo control technology, the machine's running position is more accurate, and the return is faster.

High-performance servo control technology, the machine's running position is more accurate, and the return is faster. -

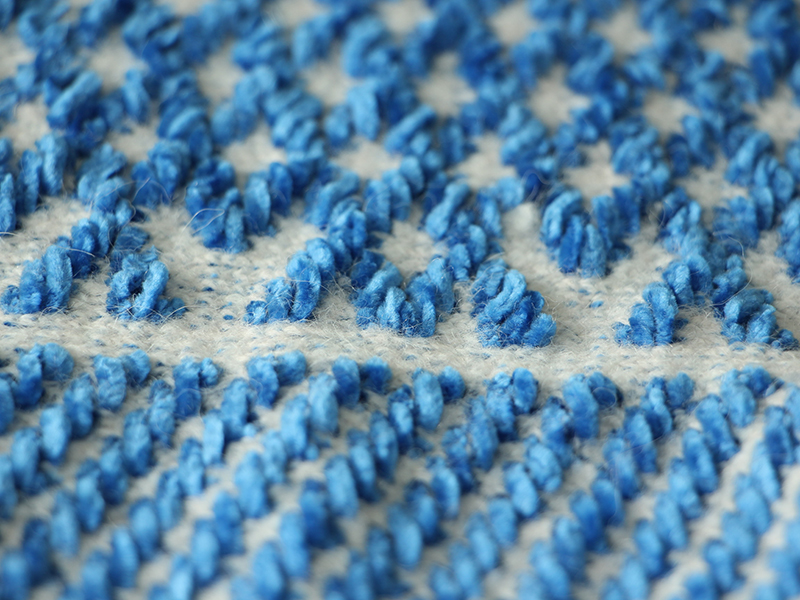

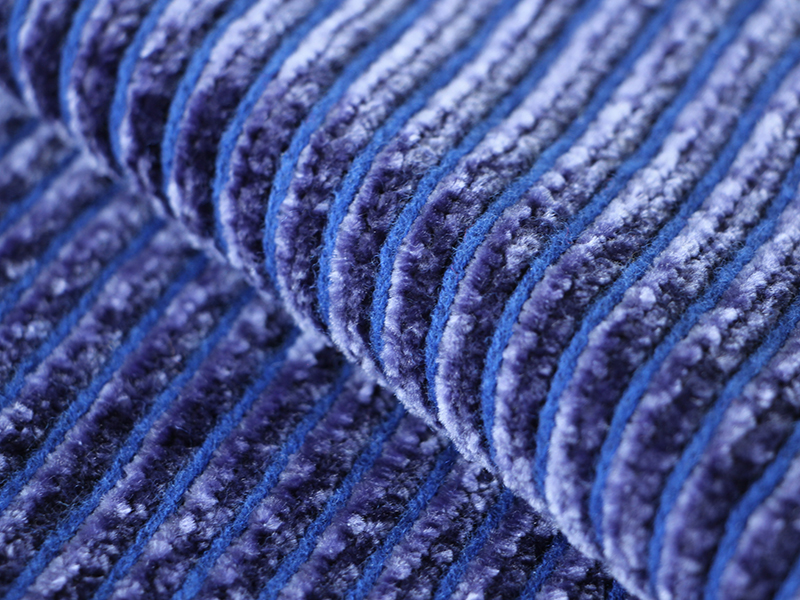

Providing stable drawing tension, make the fabric drawing more smoothly, and reliable.

Providing stable drawing tension, make the fabric drawing more smoothly, and reliable. -

The needle push system controlled by step motor make it faster, reduce the carriage return time.

The needle push system controlled by step motor make it faster, reduce the carriage return time. -

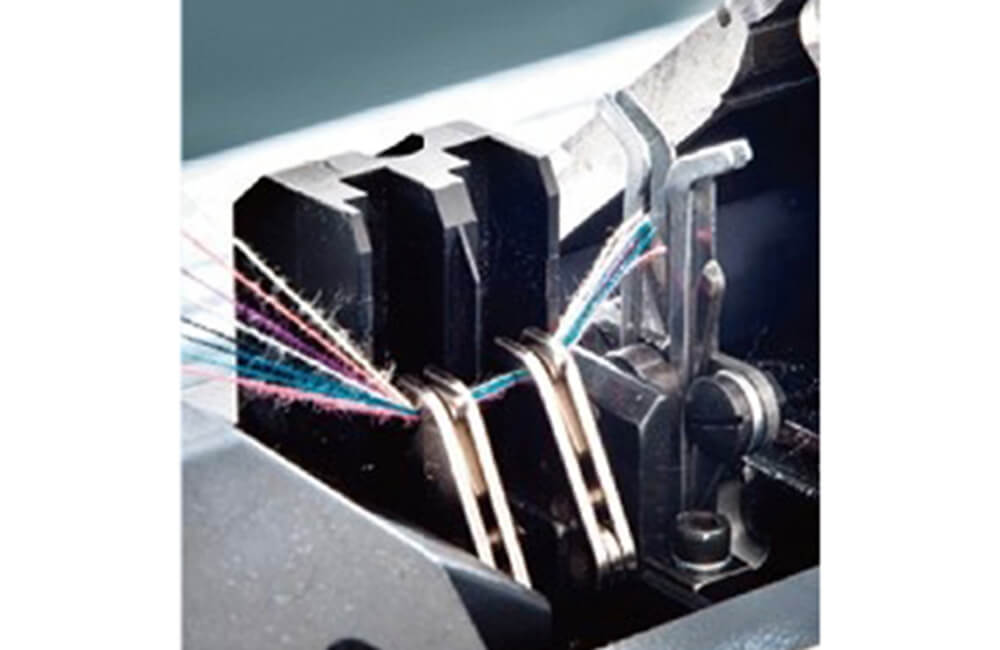

Reliable scissors and clip device for automatic yarn catch and cut operations through system control.

Reliable scissors and clip device for automatic yarn catch and cut operations through system control.

- Tel: 0086-15250337149

- E-mail: nixiaochao@gmail.com

|

LXA252/352 |

|

|

Gauge |

5G/7G(V)/8G/9G/10G/12G(V)/14G(V)/16G/18G |

|

Width |

52 inches |

|

System |

Double system/ Three system |

|

Speed |

Maximum speed 1.6m/s |

|

Racking |

Driving by servo motor, 2 inches left and right |

|

Selection system |

8-segment needle selector, pre-select needle system |

|

Sinker |

Driving by step motor, adjusting depending on fabric organization |

|

Automatic parking device |

Yarn break, yarn knot, rewinding, needle broken, pieces completed, overload, designated parking, program error, etc. |

|

safety devices |

The whole machine covers the cover that reduces noise and dust, the front and rear cover infrared stop sensor, emergency stop, power cut-off device |

|

Drawing device |

High-position roller, comb, segment adjustment |

|

Needle push mechanism |

Controlled by electromagnets for faster return |

|

Machine size and weight |

Volume: length X width X height 2650X875X1850 (mm) |

|

Power device |

Voltage: AC220V/380V Frequency: 50Hz/60Hz Power: 1.5KW |