- Tel: 0086-512-52841500

- E-mail: xsd@long-xing.net

-

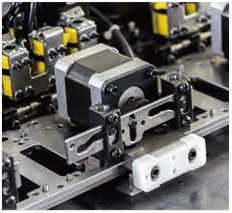

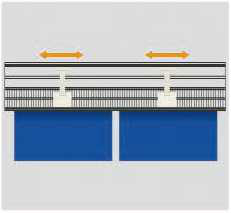

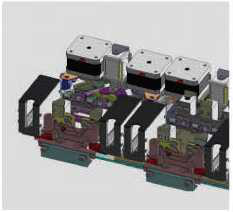

The motor push pin structure shortens the knitting stroke and makes the machine returnTurn more stable

-

Reduce the size and weight of the carriage and make the return speed faster

-

Fast inversion: The new carriage and the high performance servo technology achieve fast inversion and increase the production of 10%-20%.

-

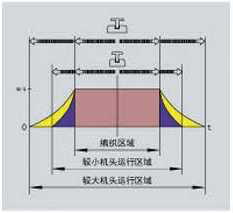

Two carriage design, separate carriage knitting is for the long type model machine to knit several pieces at the same time, which is more effectively. Also, can knit in combine state as double system

-

Adjustable tight tuck device can fully meet the special needs of the loose or tight tuck organization of the shoe upper; independent pushing needle cam control mechanism, shorten the carriage return time

-

The use of the increased thickening fabric winding roller design fully meets the higher requirements of the dou ble-sided organization fabric on the drawing force and enhances the smooth performance of the drawing.

|

Gauge |

5G,7G,3-5-7G,8G,9G,10G,12G,8-10-12G,14G,16G |

|

Knitting Width |

80inch. 100inch |

|

Knitting System |

Single carriage four system with high position roller |

|

Knitting System |

Controlled by servo motor with 32 sections speed optional max 1.4 m/s |

|

Knitting Function |

Knit, miss, tuck, transfer, pointelle, intarsia jacquard, hide or apparent shaping and other regular and irregular patterns |

|

Yarn Carrier |

2x16 yarn feeders on both sides of 1 guide rail of 8, switchover on any position of needle bed (special intarsia yarn feeders optional) |

|

Racking Patterns |

Controlled by AC servo motor racking within 2 inches and with fine micro adjustable function |

|

Dynamic Stitch |

The skill is initiation in China and at the same level with similar machines internationally. Different tightness is allowed on the same line without problem of varying lengths while knitting. When group of rib, twisted flower and front-back are knitted on the same line they are allowed to loose alone |

|

Roller |

Computerized controlled by stepping motor,32 levels selection of tension with adjustable scope 0-100, Additional Take Down (Optional) |

|

Rapid Gyration |

With rapid gyration in one-needle period, the efficiency can be raised by 14% especially when knitting narrow weaving like sleeve |

|

Protection |

The machine will atomically alarm if yarn-breaking, knots, rewind, end of knitting, fail of racking, needle jack crash, error programming occur, also with safety auto lock protection device |

|

Function of Intelligent Computer Files |

Create parameters like thickness, traction and speed with intelligent plate making program, save time for creating parameters on the machine |

|

Power |

Single-phase 220V,adopt advanced CMOS technology enabling memorizing at the instant of power outage and restoring of knitting thereafter |

|

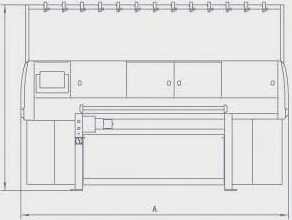

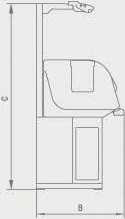

Machine Model |

Boundary Dimension' mm, |

Package Dimension: mm ) |

Net Weight( Kg )

|

Gross Weight( Kg) |

|

LXC-4100S |

4215x1150x1850 |

4515x1300x1820 |

1600 |

1850 |