- Tel: +8615250337149

- E-mail: nixiaochao@gmail.com

-

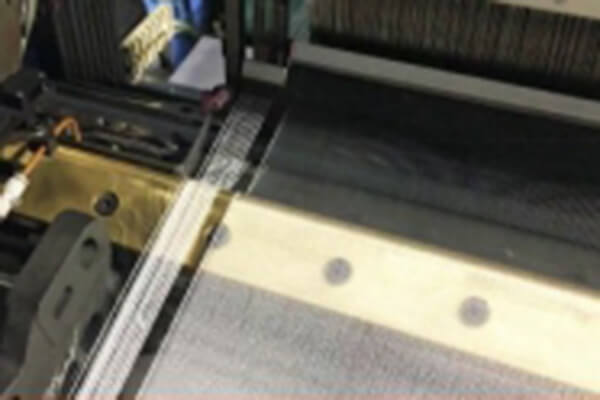

Sunshine fabric

-

Heavy industrial filter fabric

-

Carbon fiber weaving

-

Car interior fabric

-

High strength fiber weaving

-

Fully molded car airbag

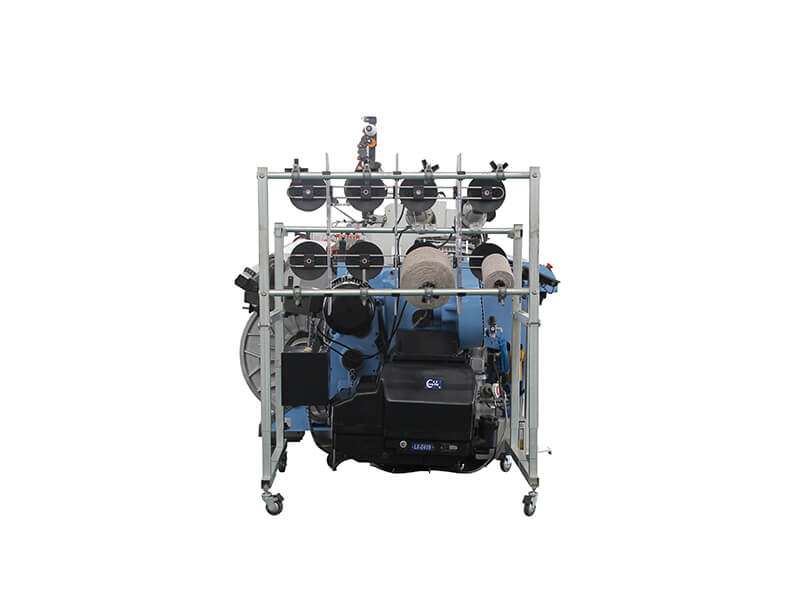

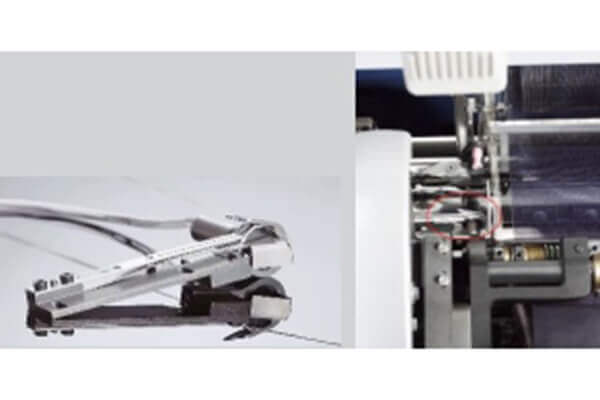

There is no gripper band guide hooks in the shed, which will not interfere with the warp yarn and is suitable for weaving most fabrics.

For easy-entangled low-strength warp yarns, the gripper band supporting teeth can be configured as a gripper band guide to prevent the gripper band from interfering with the warp yarn.

|

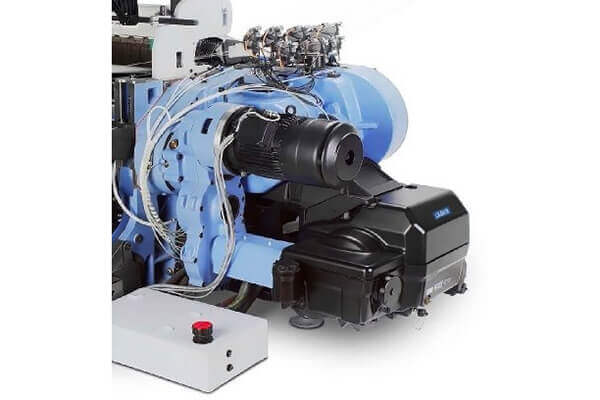

Reed width (cm) |

170、190、200、220、240、260、280、320、340、360 |

|

Shedding |

) Electronic dobby (max 20 shafts) |

|

Electronic weft selection |

4 colours, 8 colours, 12 colours |

|

Weft cutter |

Electronic RotoCut weft cutter |

|

Independent selvedge |

Independent electronic selvedge |

|

Warp beam and flange |

Single warp beam |

|

Let-off back roller |

Negative single back roller |

|

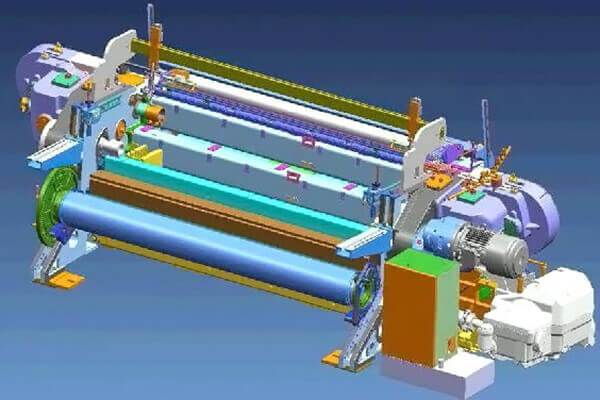

Item |

Specifications |

|

Reed width |

190、200、220、240、260、290、320、340、360 cm |

|

Reed width reduce |

0 ~ 80cm |

|

Yarn range |

Cotton and synthetic fiber yarn: 500 te(x 1.2 Ne)- 5te(x 120 Ne) |

|

Fabric weight |

40g/m2 ~ 450g/m2 |

|

Weft selection |

8 colours electronic weft selection |

|

Weft insertion |

Spatial linkage, Carbon fiber gripper band, Without gripper band guide hooks |

|

Beating |

Conjugated cams on both sides |

|

Shedding |

Electronic dobby: max 20 shafts |

|

Let-off |

Electronic let-off |

|

Take-up |

Electronic take-up |

|

Roll |

Maximum roll diameter on machine: 0600mm |

|

Selvedge |

Leno selvedge |

|

Lubrication |

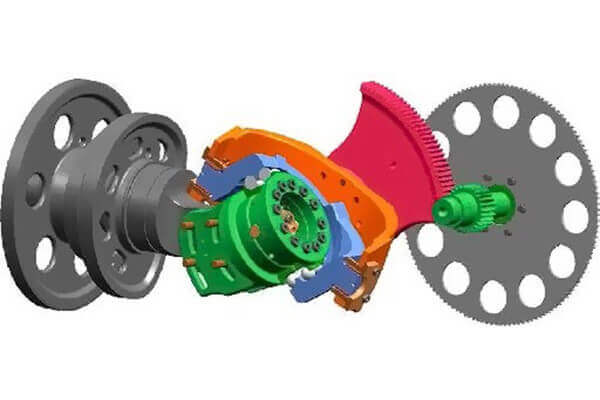

Oil bath lubrication for main transmission part |

|

Stop motion |

Weft yarn: piezoelectric ceramic weft detector |

|

Controlling |

Multi-function microcomputer control system with parameters setting/control/production management/self-diagnosis |

|

Main motor |

5.5Kw (Dobby), 7.5Kw (Jacquard) |